2018 plans and projects in the pipeline...

+11

Ted Creedon

Hampton Caught

newt5550

mconboy

potiman

turn the wheel

bmd

Sal the 2nd

brian

reeft1

Cowley

15 posters

Page 1 of 3

Page 1 of 3 • 1, 2, 3

2018 plans and projects in the pipeline...

2018 plans and projects in the pipeline...

Evening gents,

I have been mulling over a few ideas in my head for a while now, and I really want to push on with two of those over the next few weeks and months. As well as my current range of 'Limited Edition & Special Order 1/43 scale models and decals', CODE343 is also going to be broadening it's range, and branching out into silicone moulding and resin casting at first, to be followed later in the year by 3D modelling and printing.

A great deal of background research has been done into moulding and casting so far, and the raw materials are on the way to me as I type this. The first two masters have been created, and it is these which - if they turn out as good as I am hoping they do - will be available to purchase should anybody have a need for them. If not, then they will simply be used to develop and refine the various stages of the process.

I am aware that Simon (Jones) has also produced some superb resin cast Metro 6R4 rallycross bodyshells, but has anyone else had a dabble in 'the art', and if so, do you have any tips or recommendations that I might find useful?

Additional 1/43 scale MG Metro 6R4 decal sets will be added to the current CODE343 range in the next couple of weeks - watch this space...

I have been mulling over a few ideas in my head for a while now, and I really want to push on with two of those over the next few weeks and months. As well as my current range of 'Limited Edition & Special Order 1/43 scale models and decals', CODE343 is also going to be broadening it's range, and branching out into silicone moulding and resin casting at first, to be followed later in the year by 3D modelling and printing.

A great deal of background research has been done into moulding and casting so far, and the raw materials are on the way to me as I type this. The first two masters have been created, and it is these which - if they turn out as good as I am hoping they do - will be available to purchase should anybody have a need for them. If not, then they will simply be used to develop and refine the various stages of the process.

I am aware that Simon (Jones) has also produced some superb resin cast Metro 6R4 rallycross bodyshells, but has anyone else had a dabble in 'the art', and if so, do you have any tips or recommendations that I might find useful?

Additional 1/43 scale MG Metro 6R4 decal sets will be added to the current CODE343 range in the next couple of weeks - watch this space...

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

My own limited experience was covered in this thread from a few years back David.

https://www.diecastrallymodels.com/t3930-mould-making?highlight=mould

https://www.diecastrallymodels.com/t3930-mould-making?highlight=mould

reeft1- Posts : 3415

Join date : 2012-02-14

Age : 55

Location : Essex

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Gave it a try a few years ago. Making your mould is the most important thing. Once you plan out what you need, decide on where your pour spot will be and if you need any extra spouts to let out any air.

Second thing is to degas the resin after you pour it in. Loads of tutorials on pouring correctly to degas, but you can make a cheap degasing chamber really quickly using a vacuum storage bag

Second thing is to degas the resin after you pour it in. Loads of tutorials on pouring correctly to degas, but you can make a cheap degasing chamber really quickly using a vacuum storage bag

_________________

Always interested in 1/18 Irish Decals/models

brian- Posts : 2009

Join date : 2012-02-07

Age : 37

Location : Waterford

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Will watch developments with interest! Just seen that Trofeu are re-releasing the Marlboro liveried Celica with "3d printed lamp pod" so when the mainstream boys are getting in on the act it shows it its the way to go.

Sal the 2nd- Posts : 769

Join date : 2016-08-08

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Well, there's a thing, Paul!reeft1 wrote:My own limited experience was covered in this thread from a few years back David.

https://www.diecastrallymodels.com/t3930-mould-making?highlight=mould

I had forgotten all about that 2013/2014 thread - even though I actually contributed to it at the time, and expressed an interest in also having a go myself, as well. Reading it through all these years on, it's quite encouraging to see what results your ended up with, and photos of the various stages are also immensely helpful too. They not only answer some questions, but also generate others in equal measures.

Many thanks for your input, and for reminding me of the thread.

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Thank you to yourself also, Brian.brian wrote:Gave it a try a few years ago. Making your mould is the most important thing. Once you plan out what you need, decide on where your pour spot will be and if you need any extra spouts to let out any air.

Second thing is to degas the resin after you pour it in. Loads of tutorials on pouring correctly to degas, but you can make a cheap degasing chamber really quickly using a vacuum storage bag

I see you also got involved in that old thread that Paul linked too.

Many thanks for your input, Brian.

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

3D modelling and printing is a much more distant 'wish', Chris.Sal the 2nd wrote:Will watch developments with interest! Just seen that Trofeu are re-releasing the Marlboro liveried Celica with "3d printed lamp pod" so when the mainstream boys are getting in on the act it shows it its the way to go.

I have downloaded some software though, and plan to attempt to draw a few simple shapes first, and see how 'user-friendly' the package is to develop those into more complicated shapes. Wheels and dashboards are my main area of focus for 3D modelling and printing if I do manage to master the art to a suitable quality, however.

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

'DC' has been shopping today!...

Lego, check!

Plasticine, check!

Vaseline, check!

Modelling tools, check!

Kitchen tiles, check!

White Spirit, check!

Stainless steel mixing bowls, check!

Domed nuts, check!

Two-Part Mould Making Silicone and Two-Part Casting Resin on the way, check!

Lego, check!

Plasticine, check!

Vaseline, check!

Modelling tools, check!

Kitchen tiles, check!

White Spirit, check!

Stainless steel mixing bowls, check!

Domed nuts, check!

Two-Part Mould Making Silicone and Two-Part Casting Resin on the way, check!

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

hope no-one reads that out of context david, items 3 and 8 might get them wondering what you do in your man-cave!!

bmd- Posts : 7018

Join date : 2012-02-12

Age : 57

Location : here

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

I did wonder about mentioning the petroleum jelly based lubricant at the time, Billy - but domed nuts never even crossed my mind!

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

my bad mind david, apologies from this side of the water.....

bmd- Posts : 7018

Join date : 2012-02-12

Age : 57

Location : here

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

It's all in your mind, Billy!!

Very interested to follow what you have planned, David. Whether decals or bigger things, I'll keep my eyes open.

Have been pondering the resin route on and off for two or three years and more recently, 3D printing. Had been hatching plans with Jordan Bowes, rallycross driver back in late October last year but he was killed in a road accident the following day so we didn't get anywhere, sadly.

Question is, what are you going to be making from your resin-related purchases, I wonder? Consideroing your earlier comment about Simon's 6R4s, I'm wonderign if you're going the Rover SD1 route and making each of the runners in the Austin Rover Rallysprint event from Donnigton Park? After all, they used the same car with different decals for each of the drivers?

Whatever, I'm very interested to see what you have in the pipeline - just don't keep us waiting too long!

Cheers, Steve

Very interested to follow what you have planned, David. Whether decals or bigger things, I'll keep my eyes open.

Have been pondering the resin route on and off for two or three years and more recently, 3D printing. Had been hatching plans with Jordan Bowes, rallycross driver back in late October last year but he was killed in a road accident the following day so we didn't get anywhere, sadly.

Question is, what are you going to be making from your resin-related purchases, I wonder? Consideroing your earlier comment about Simon's 6R4s, I'm wonderign if you're going the Rover SD1 route and making each of the runners in the Austin Rover Rallysprint event from Donnigton Park? After all, they used the same car with different decals for each of the drivers?

Whatever, I'm very interested to see what you have in the pipeline - just don't keep us waiting too long!

Cheers, Steve

Hampton Caught- Posts : 2385

Join date : 2012-02-09

Age : 56

Location : near Hampton Court

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

bmd wrote:my bad mind david, apologies from this side of the water.....

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Many thanks, Steve.Hampton Caught wrote:It's all in your mind, Billy!!

Very interested to follow what you have planned, David. Whether decals or bigger things, I'll keep my eyes open.

Have been pondering the resin route on and off for two or three years and more recently, 3D printing. Had been hatching plans with Jordan Bowes, rallycross driver back in late October last year but he was killed in a road accident the following day so we didn't get anywhere, sadly.

Question is, what are you going to be making from your resin-related purchases, I wonder? Consideroing your earlier comment about Simon's 6R4s, I'm wonderign if you're going the Rover SD1 route and making each of the runners in the Austin Rover Rallysprint event from Donnigton Park? After all, they used the same car with different decals for each of the drivers?

Whatever, I'm very interested to see what you have in the pipeline - just don't keep us waiting too long!

Cheers, Steve

Trials are indeed going well, and I am very pleased with the first couple of mouldings and castings. All being well, I will have some further details over the weekend. The first items are more useful for myself than anything that I could sell a bucket load of to fellow modellers, however if there is any interest shown, then I would happily make enough available to purchase.

Further details to follow over the weekend....

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Best of Luck everybody concerned!!!!!!!!!!!!! Looking forward to the finished product !!!!!! Products

turn the wheel- Posts : 1070

Join date : 2012-02-12

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

You could potentially sell a bucket load David?? Must be a Ford rather than one of those lefty rust buckets

reeft1- Posts : 3415

Join date : 2012-02-14

Age : 55

Location : Essex

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

As I have a somewhat biased tendency towards the MG Metro 6R4 and their 1/43 scale variants, my first couple of trials were always bound to feature elements of that particular car, and the following detailed stages of the process would back up that assumption!  Other non-Metro 6R4 based subjects, can follow once the process has been fully refined....

Other non-Metro 6R4 based subjects, can follow once the process has been fully refined....

I have always wanted to create an open model of a Metro with added interior detail, and we all know how labour intensive it is to Dremel and file away a complete door from a bodyshell. As it would be impossible to retain a fully intact door from the same bodyshell, two bodyshells are actually required - one complete bodyshell without the door, and another bodyshell that would yield a complete door to position in the 'open' format. The latter can then also be used to yield the opposite side door, tailgate, bonnet, front bumper, spoiulers, etc for future 'open' project builds.

Due to the labour involved in creating the above, I thought I would use the driver's door as the first trial for my new silicone moulding and resin casting project. The second trial would be a fully detailed interior door card for a Metro 6R4 'Clubman' car, based upon one scratch built in plastic card, strip, rod, etc.

Following all of the supplies, materials and equipment arriving from the various sources, I could now start planning how each individual mould would be created, and this is the most important part of the process. No matter how good the original master is, or how good the eventual moulds are, if you don't plan how the resin is going to flow through or over the mould(s), then it could quite easily all end up completely 'Pete Tong'!

I have always wanted to create an open model of a Metro with added interior detail, and we all know how labour intensive it is to Dremel and file away a complete door from a bodyshell. As it would be impossible to retain a fully intact door from the same bodyshell, two bodyshells are actually required - one complete bodyshell without the door, and another bodyshell that would yield a complete door to position in the 'open' format. The latter can then also be used to yield the opposite side door, tailgate, bonnet, front bumper, spoiulers, etc for future 'open' project builds.

Due to the labour involved in creating the above, I thought I would use the driver's door as the first trial for my new silicone moulding and resin casting project. The second trial would be a fully detailed interior door card for a Metro 6R4 'Clubman' car, based upon one scratch built in plastic card, strip, rod, etc.

Following all of the supplies, materials and equipment arriving from the various sources, I could now start planning how each individual mould would be created, and this is the most important part of the process. No matter how good the original master is, or how good the eventual moulds are, if you don't plan how the resin is going to flow through or over the mould(s), then it could quite easily all end up completely 'Pete Tong'!

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Mmmmmm! Very interesting, David!

I admire your bravery and am excitied to see and hear about the results. Go for it!!!

Cheers, Steve

I admire your bravery and am excitied to see and hear about the results. Go for it!!!

Cheers, Steve

Hampton Caught- Posts : 2385

Join date : 2012-02-09

Age : 56

Location : near Hampton Court

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Trial #1 : MG Metro 6R4 Driver's Door

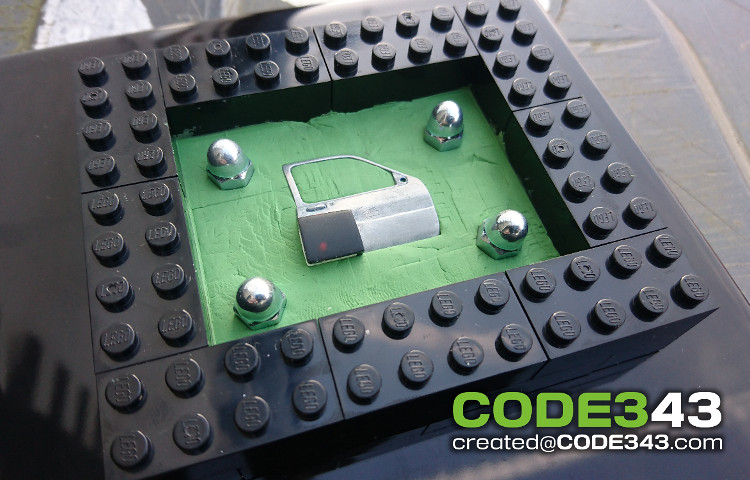

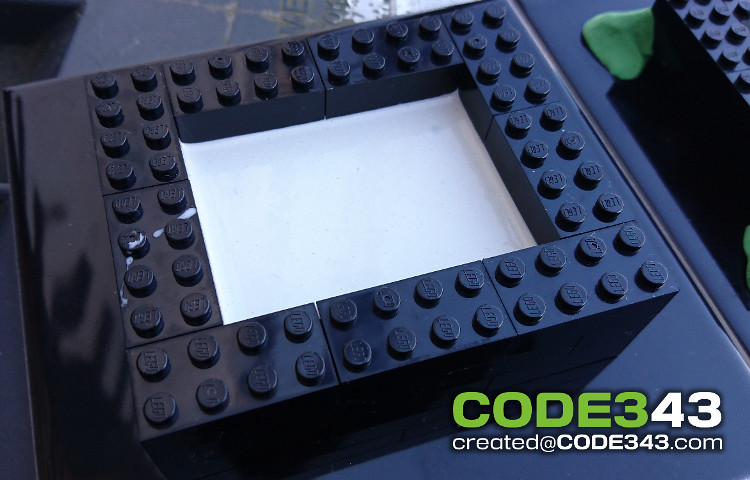

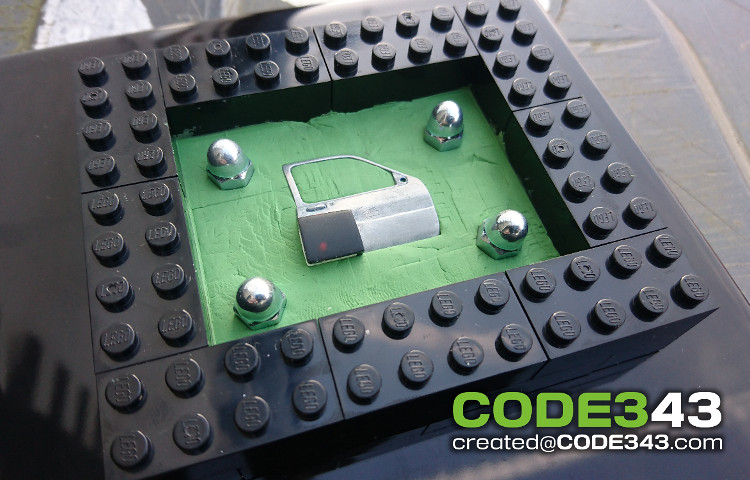

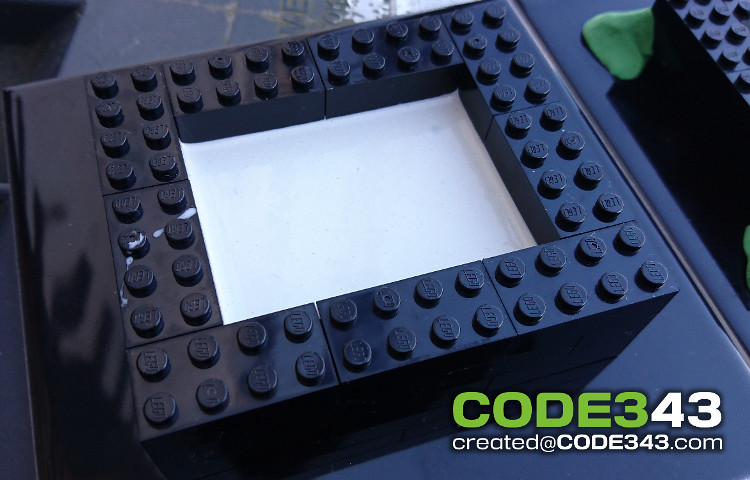

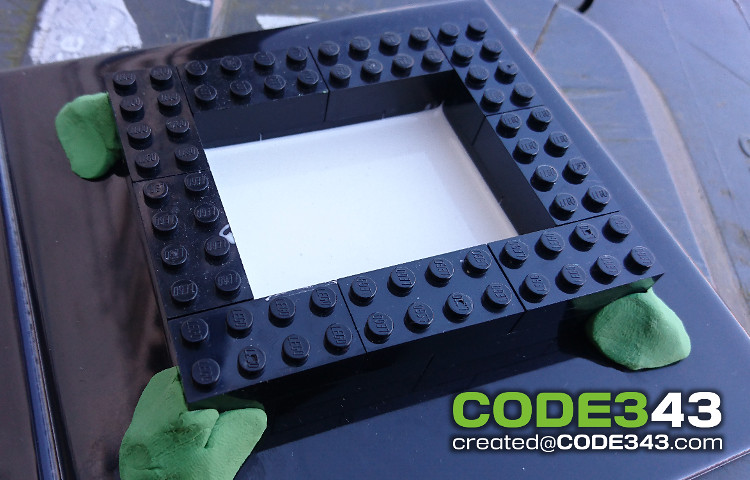

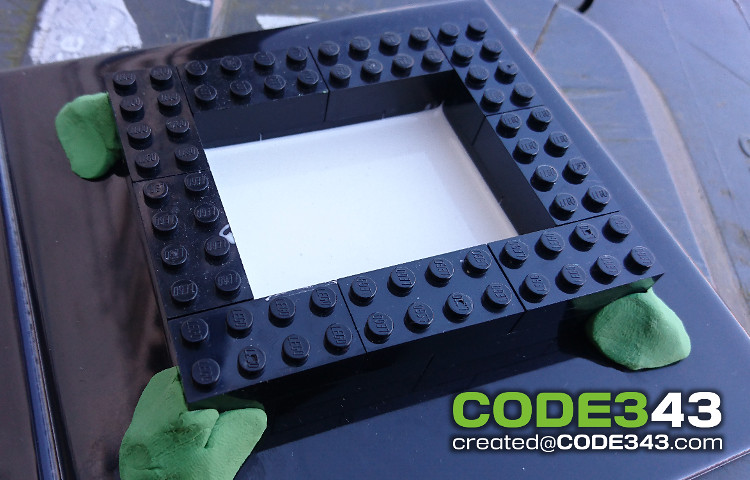

I decided on a two-part silicone mould, with the join being positioned around the 'circumference' of the door. The following photo shows a 6" ceramic tile used as a moulding surface - primarily because it was nice and small, light, perfectly flat, non absorbing, and with a glass like finish. On top of that I built a moulding box from Lego, two blocks high, and then pressed sufficient Plasticine in to the bottom to 'half fill' the moulding box. The Plasticine serves two purposes - it not only holds the master of the door when you create the first part of your silicone mould, but it also 'locks' the Lego moulding box to the ceramic tile.

Once I was happy that the top of the Plasticine was flat enough, and pressed in to all four corners, I literally pressed the door into the middle of the Plasticine up to where I wanted the join to be around the 'circumference' of the door. Modelling tools were then used to manipulate the Plasticine up to the door, or away from the door as required.

Four small 5mm domed nuts were then pressed into the Plasticine, and these would become the four registration points between the two-part 'male' and 'female' halves of the mould. Here is a photo of the process up to this point...

There are various different silicone products that can be used, and the method for mixing and handling those is more than likely, completely different, so I will not deal with that stage of the process here - all you will need to do is work out the area of silicone required and mix sufficient of your relevant product.

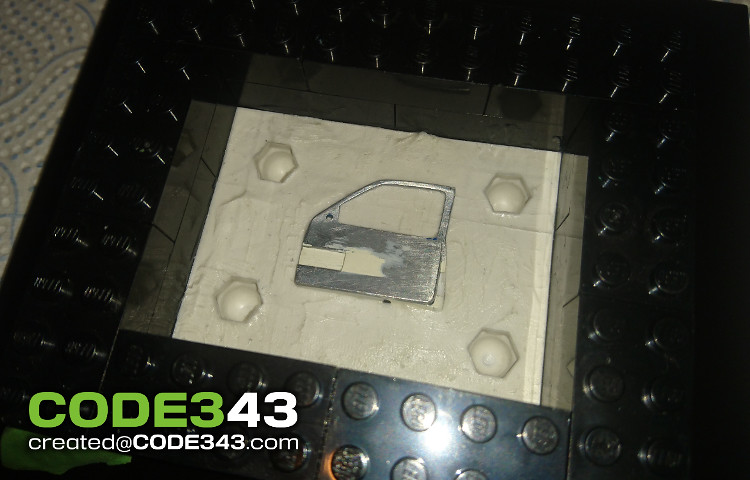

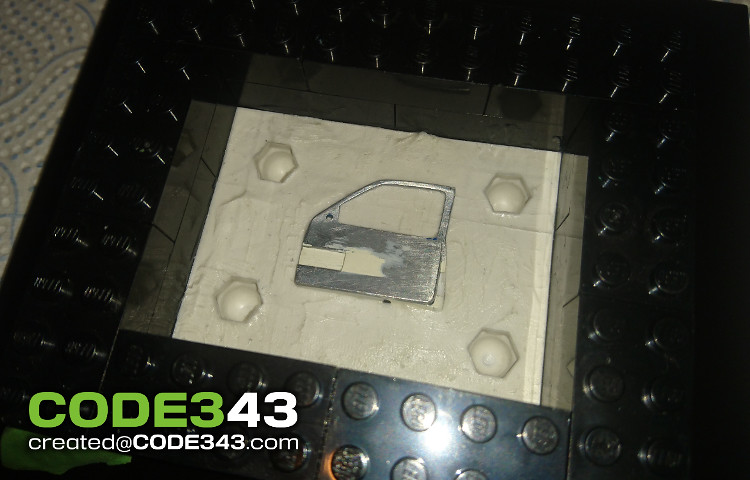

There is a great deal of advice about using various methods or equipment for removing air bubbles from silicone, but I found if you pour it in a fine stream from about 1 foot above your moulding box, the stream is that thin and long, that the majority of the bubbles will be removed from the silicone in the pouring process - some will even simply rise to the surface during the curing process. Here is a photo of the process up to this point...

The silicone that I used needed overnight to fully cure in the moulding box, and as stated earlier, other products will behave differently. This is where 'Patience Is A Virtue #1' comes in to play, as the excitement and apprehension is unbearable, and you are dying to crack open the Lego, and see what the mould has turned out like, but any early intervention could easily ruin all that hard work to date, so be patient!

Once the time has come, the moulding box can be cracked open, and you can check the quality of the 'female' moulding. Clean any Plasticine residue from your master - the Metro 6R4 driver's door in my case - the Lego blocks, and the ceramic tile, using White Spirit on a cotton bud or a sheet of tissue. Any silicone 'flashing' caused by the liquid silicone running into the miniscule gaps between the Lego blocks can be simply pulled away between your fingers without damaging the mould itself, and then chamfer the four edges of the outside surface using a craft knife so that it will sit flat when inverted.

The next stage is to make the 'male' part of the mould. An identical two-block high moulding box can be rebuilt using the cleaned Lego, and using four blobs of Plasticine, 'lock it' down to the same 6" ceramic tile used earlier. Silicone moulding requires a releasing agent so that the liquid silicone that you pour in to the moulding box (to create your second half of the mould) doesn't just stick to the cured first half. There are various sprays you can buy, but I was recommended Vaseline (Honest, Billy! ) diluted with White Spirit in an approx 70 / 30 mix - but as long as it makes the Vaseline brushable, then the mix ratio doesn't really matter as the White Spirit will evaporate anyway. All you need to do is ensure that the whole surface of the first 'female' mould is covered with the mix, as if there is any missing and the liquid silicone is allowed to touch the cured silicone, then I am pretty sure that both moulds will be useless and will need remaking from scratch! Just take a little extra time her to ensure you have it all covered - including the four registration points made by the four domed nuts.

) diluted with White Spirit in an approx 70 / 30 mix - but as long as it makes the Vaseline brushable, then the mix ratio doesn't really matter as the White Spirit will evaporate anyway. All you need to do is ensure that the whole surface of the first 'female' mould is covered with the mix, as if there is any missing and the liquid silicone is allowed to touch the cured silicone, then I am pretty sure that both moulds will be useless and will need remaking from scratch! Just take a little extra time her to ensure you have it all covered - including the four registration points made by the four domed nuts.

Once you are confident that you have the silicone 'join' covered in Vaseline / White Spirit, press the master back into the mould so that is sits in exactly the same position. Here is a photo of the process up to this point...

Mix the required amount of silicone, and with your pouring container about 1 foot above the moulding box, carefully pour the liquid silicone in. This can be done slowly so that you can control where the silicone flows to if you have any complicated sections on your master - you can even stop if you want to wait a few seconds for it to flow where you want. In my case, the Metro's door box was an area that I was concerned about, so I ensured there were no air bubbles within it before I increased the flow to fill the remainder of the moulding box.

This is where 'Patience Is A Virtue #2' comes in to play and you have to wait for it to cure, overnight or 12 hours for the silicone product that I was using. This is also quite nerve-wracking as you don't really know if you have used enough of the Vaseline / White Spirit mix, or if you have covered the whole surface adequately! Once you feel happy, repeat the process of cracking the mould, cleaning the Lego and the master with White Spirit, removing the silicone 'flashing' with your fingers, and chamfering the four edges of the second 'male' half of the two-part mould.

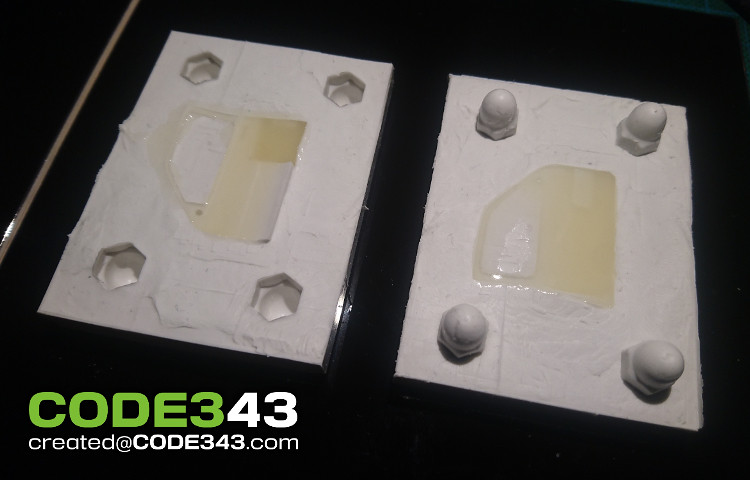

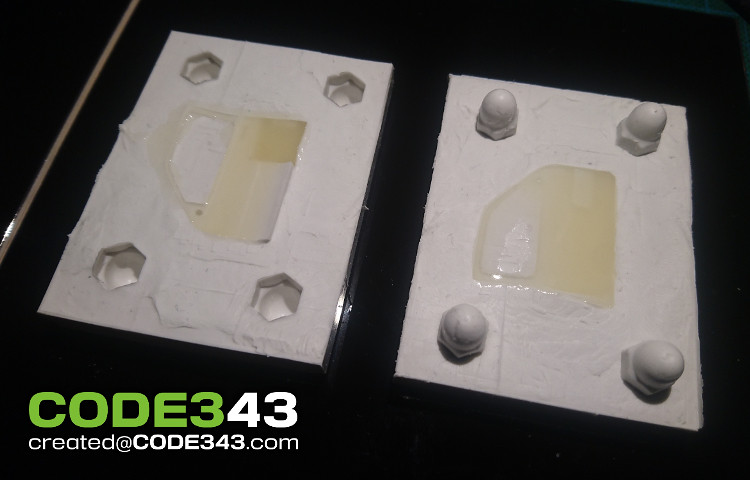

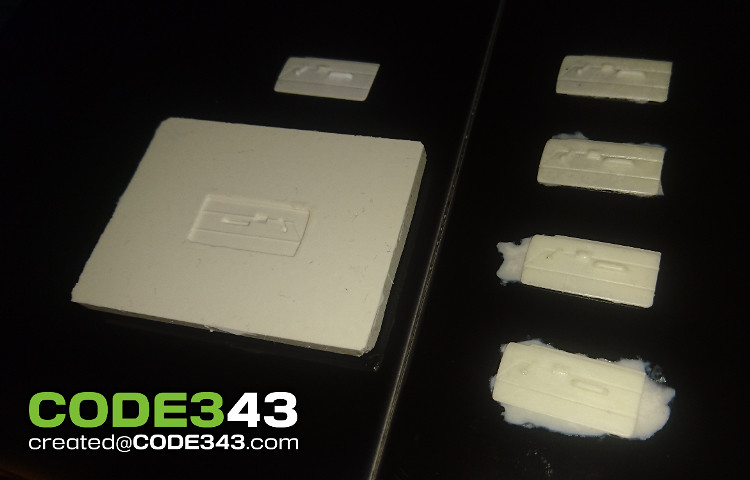

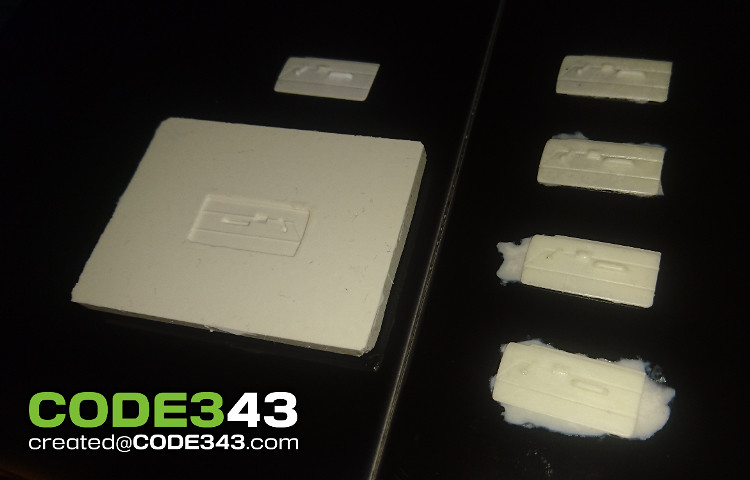

My original plan of how I would fill this mould with resin did not require the inclusion of a pouring hole or a vent hole, so I did not include one in the mould making process. My two moulds would be filled with resin, allowed to 'go off' for a few minutes so that they become more solid than liquid, and then one mould was simply inverted, 'mated' up with the opposite mould using the four domed nut shaped registration points, and then a small weight was placed on the top whilst the resin cured. This method simply requires a little more resin in each half than you actually need, so that once they are pressed together, a certain amount of excess is pressed out between the 'join', and this can be cleaned off when fully cured. Here is a photo of the process up to this point...

The resin that I was using goes off in 7-8 minutes, can be de-moulded in 1-1.5 hours, and is fully cured in 72 hours, but this all depends on the thickness of the resin throughout various parts of the mould. This is where the final 'Patience Is A Virtue #3' comes in to play as you are dying to see what your first prototype is like, if the moulding has recreated an identical copy of your master item, and if the resin has indeed flowed into all the required areas of the two-part moulding! It is best to be safe and ensure that it is fully cured though before you do try to release the casting from between the two mould halves.

Here is the final photo showing the last stages of the process, with the two moulds full of liquid resin while I wait for them to 'go off' a little before inverting one half on to the other. Top right is the original master door, and below that is a cleaned up resin door in the middle, and a rough resin casting that has only just come out of the moulds and has yet to be cleaned up...

Trial #2 - Metro 6R4 Clubman Door Card details to follow later...

I decided on a two-part silicone mould, with the join being positioned around the 'circumference' of the door. The following photo shows a 6" ceramic tile used as a moulding surface - primarily because it was nice and small, light, perfectly flat, non absorbing, and with a glass like finish. On top of that I built a moulding box from Lego, two blocks high, and then pressed sufficient Plasticine in to the bottom to 'half fill' the moulding box. The Plasticine serves two purposes - it not only holds the master of the door when you create the first part of your silicone mould, but it also 'locks' the Lego moulding box to the ceramic tile.

Once I was happy that the top of the Plasticine was flat enough, and pressed in to all four corners, I literally pressed the door into the middle of the Plasticine up to where I wanted the join to be around the 'circumference' of the door. Modelling tools were then used to manipulate the Plasticine up to the door, or away from the door as required.

Four small 5mm domed nuts were then pressed into the Plasticine, and these would become the four registration points between the two-part 'male' and 'female' halves of the mould. Here is a photo of the process up to this point...

There are various different silicone products that can be used, and the method for mixing and handling those is more than likely, completely different, so I will not deal with that stage of the process here - all you will need to do is work out the area of silicone required and mix sufficient of your relevant product.

There is a great deal of advice about using various methods or equipment for removing air bubbles from silicone, but I found if you pour it in a fine stream from about 1 foot above your moulding box, the stream is that thin and long, that the majority of the bubbles will be removed from the silicone in the pouring process - some will even simply rise to the surface during the curing process. Here is a photo of the process up to this point...

The silicone that I used needed overnight to fully cure in the moulding box, and as stated earlier, other products will behave differently. This is where 'Patience Is A Virtue #1' comes in to play, as the excitement and apprehension is unbearable, and you are dying to crack open the Lego, and see what the mould has turned out like, but any early intervention could easily ruin all that hard work to date, so be patient!

Once the time has come, the moulding box can be cracked open, and you can check the quality of the 'female' moulding. Clean any Plasticine residue from your master - the Metro 6R4 driver's door in my case - the Lego blocks, and the ceramic tile, using White Spirit on a cotton bud or a sheet of tissue. Any silicone 'flashing' caused by the liquid silicone running into the miniscule gaps between the Lego blocks can be simply pulled away between your fingers without damaging the mould itself, and then chamfer the four edges of the outside surface using a craft knife so that it will sit flat when inverted.

The next stage is to make the 'male' part of the mould. An identical two-block high moulding box can be rebuilt using the cleaned Lego, and using four blobs of Plasticine, 'lock it' down to the same 6" ceramic tile used earlier. Silicone moulding requires a releasing agent so that the liquid silicone that you pour in to the moulding box (to create your second half of the mould) doesn't just stick to the cured first half. There are various sprays you can buy, but I was recommended Vaseline (Honest, Billy!

Once you are confident that you have the silicone 'join' covered in Vaseline / White Spirit, press the master back into the mould so that is sits in exactly the same position. Here is a photo of the process up to this point...

Mix the required amount of silicone, and with your pouring container about 1 foot above the moulding box, carefully pour the liquid silicone in. This can be done slowly so that you can control where the silicone flows to if you have any complicated sections on your master - you can even stop if you want to wait a few seconds for it to flow where you want. In my case, the Metro's door box was an area that I was concerned about, so I ensured there were no air bubbles within it before I increased the flow to fill the remainder of the moulding box.

This is where 'Patience Is A Virtue #2' comes in to play and you have to wait for it to cure, overnight or 12 hours for the silicone product that I was using. This is also quite nerve-wracking as you don't really know if you have used enough of the Vaseline / White Spirit mix, or if you have covered the whole surface adequately! Once you feel happy, repeat the process of cracking the mould, cleaning the Lego and the master with White Spirit, removing the silicone 'flashing' with your fingers, and chamfering the four edges of the second 'male' half of the two-part mould.

My original plan of how I would fill this mould with resin did not require the inclusion of a pouring hole or a vent hole, so I did not include one in the mould making process. My two moulds would be filled with resin, allowed to 'go off' for a few minutes so that they become more solid than liquid, and then one mould was simply inverted, 'mated' up with the opposite mould using the four domed nut shaped registration points, and then a small weight was placed on the top whilst the resin cured. This method simply requires a little more resin in each half than you actually need, so that once they are pressed together, a certain amount of excess is pressed out between the 'join', and this can be cleaned off when fully cured. Here is a photo of the process up to this point...

The resin that I was using goes off in 7-8 minutes, can be de-moulded in 1-1.5 hours, and is fully cured in 72 hours, but this all depends on the thickness of the resin throughout various parts of the mould. This is where the final 'Patience Is A Virtue #3' comes in to play as you are dying to see what your first prototype is like, if the moulding has recreated an identical copy of your master item, and if the resin has indeed flowed into all the required areas of the two-part moulding! It is best to be safe and ensure that it is fully cured though before you do try to release the casting from between the two mould halves.

Here is the final photo showing the last stages of the process, with the two moulds full of liquid resin while I wait for them to 'go off' a little before inverting one half on to the other. Top right is the original master door, and below that is a cleaned up resin door in the middle, and a rough resin casting that has only just come out of the moulds and has yet to be cleaned up...

Trial #2 - Metro 6R4 Clubman Door Card details to follow later...

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Dave

As they say patience is a virtue and for the first effort it looks like a good result.

Once you get confident with the process the production line will be rolling

Well done Dave a very interesting insight into a new process

Chris

As they say patience is a virtue and for the first effort it looks like a good result.

Once you get confident with the process the production line will be rolling

Well done Dave a very interesting insight into a new process

Chris

CDM- Posts : 1293

Join date : 2012-02-10

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Great work, David.

Great shots showing the process and I like the last shot with the doors at different stages. Very neat.

Keen to see your progress.

Cheers, Steve

Great shots showing the process and I like the last shot with the doors at different stages. Very neat.

Keen to see your progress.

Cheers, Steve

Hampton Caught- Posts : 2385

Join date : 2012-02-09

Age : 56

Location : near Hampton Court

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Good morning gents, and many many thanks for the kind words.

It really is quite rewarding, and I am indeed looking forward to creating more and more complex subjects in due course. My goal could quite possibly be my own range of 1/43 scale accessories, and ultimately maybe even a complete model kit, but further trials (and tribulations? lol) are required before this latter stage. It's the only way to learn...

Trial #2 - Metro 6R4 Clubman Door Card

In contrast to the driver's door, the moulding and casting of this item was going to be handled quite differently - purely down to the thickness, shape, and individual characteristics of the item, in comparison.

Once the driver's door master had been created, I took some time to make a matching door card master made from plastic card, and various different profiles of plastic strip, and plastic rod. After checking the detail of the full size door card, I realised that my master would not only have to feature the relevant panel lines in the trim, but also a window winder, and both interior door handles - to open the door from the inside, and to pull it shut as well. I also wanted the door card to stick up slighly above the top of the door by approx 0.5mm - this is a method that I have used in the past, and when representating a window half wound down (or half up if you are an optimist! lol), it gives you just enough surface to Clear Fix a piece of shaped clear plastic to, to represent the side window.

Thinking about how the resin would flow throughout the silicone mould, it didn't take me long to realise that a one-piece 'female' mould would be my best option. Everything else applies as per creating my other moulds, so I will refrain from going in to the identical details here.

All I will say is that I mix up a very small amount of resin - in fact, it has been literally what I have had left over from casting another door, such is the small amount required. I then pour it slowly into the mould ensuring the resin flows across it. Using a cocktail stick I press the end lightly into the lower areas of the mould to ensure there are no air bubbles in the interior details. If you feel you have over-filled your mould, and have an bulging miniscus on the top!, simply scrape across the top with a straight-edged piece of plastic card, to remove any excess towards the edge of the mould, and wipe away with a tissue. Leave the resin to cure for the appropriate amount of time, and then simply bend back the silicone mould, and the resin door card will 'pop out'.

Here are the various photos throughout the process - the first one shows that I didn't need to use Plasticine to create this mould, I simply glued the door card to the ceramic tile instead, and as the latter has a smooth glass like finish it is ideal to use as a moulding surface....

Below is the final photo showing the last stages of the process, with the single mould full of liquid resin while I wait for it to cure. Top right is the original plastic master door card, and below that is an assortment of resin door cards that have yet to be cleaned up...

My next item will be to create an identical plastic card master for the co-driver / passenger side door card, and make a batch of those in resin as well. Once I have sufficient sets made up, depending on interest they will become the first 1/43 scale accessories available from CODE343 - watch this space for news of this, and any other additions to the range!...

It really is quite rewarding, and I am indeed looking forward to creating more and more complex subjects in due course. My goal could quite possibly be my own range of 1/43 scale accessories, and ultimately maybe even a complete model kit, but further trials (and tribulations? lol) are required before this latter stage. It's the only way to learn...

Trial #2 - Metro 6R4 Clubman Door Card

In contrast to the driver's door, the moulding and casting of this item was going to be handled quite differently - purely down to the thickness, shape, and individual characteristics of the item, in comparison.

Once the driver's door master had been created, I took some time to make a matching door card master made from plastic card, and various different profiles of plastic strip, and plastic rod. After checking the detail of the full size door card, I realised that my master would not only have to feature the relevant panel lines in the trim, but also a window winder, and both interior door handles - to open the door from the inside, and to pull it shut as well. I also wanted the door card to stick up slighly above the top of the door by approx 0.5mm - this is a method that I have used in the past, and when representating a window half wound down (or half up if you are an optimist! lol), it gives you just enough surface to Clear Fix a piece of shaped clear plastic to, to represent the side window.

Thinking about how the resin would flow throughout the silicone mould, it didn't take me long to realise that a one-piece 'female' mould would be my best option. Everything else applies as per creating my other moulds, so I will refrain from going in to the identical details here.

All I will say is that I mix up a very small amount of resin - in fact, it has been literally what I have had left over from casting another door, such is the small amount required. I then pour it slowly into the mould ensuring the resin flows across it. Using a cocktail stick I press the end lightly into the lower areas of the mould to ensure there are no air bubbles in the interior details. If you feel you have over-filled your mould, and have an bulging miniscus on the top!, simply scrape across the top with a straight-edged piece of plastic card, to remove any excess towards the edge of the mould, and wipe away with a tissue. Leave the resin to cure for the appropriate amount of time, and then simply bend back the silicone mould, and the resin door card will 'pop out'.

Here are the various photos throughout the process - the first one shows that I didn't need to use Plasticine to create this mould, I simply glued the door card to the ceramic tile instead, and as the latter has a smooth glass like finish it is ideal to use as a moulding surface....

Below is the final photo showing the last stages of the process, with the single mould full of liquid resin while I wait for it to cure. Top right is the original plastic master door card, and below that is an assortment of resin door cards that have yet to be cleaned up...

My next item will be to create an identical plastic card master for the co-driver / passenger side door card, and make a batch of those in resin as well. Once I have sufficient sets made up, depending on interest they will become the first 1/43 scale accessories available from CODE343 - watch this space for news of this, and any other additions to the range!...

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Thank you, mate - time will tell if these trials unearth any saleable products in the end!...turn the wheel wrote:Best of Luck everybody concerned!!!!!!!!!!!!! Looking forward to the finished product !!!!!! Products

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Ha ha ha ha ha ha!...reeft1 wrote:You could potentially sell a bucket load David?? Must be a Ford rather than one of those lefty rust buckets

Thank you, mate. I am however always open to suggestions of any casting that might potentially be a good seller - Dagenham dustbin or not!

Certainly 1/43 scale resin Metro 6R4 kits have been available for over 30 years, and they still crop up on eBay from time to time as well, so that is ceratinly not part of my plans for a complete model kit. That thought is currently lying with another non BMC / BL / ARG / MGR based manufacturer...

Re: 2018 plans and projects in the pipeline...

Re: 2018 plans and projects in the pipeline...

Most Impressed David !!

Wonderfully detailed explanation of the process.

Can't wait for the next instalment!

David L

Wonderfully detailed explanation of the process.

Can't wait for the next instalment!

David L

potiman- Posts : 242

Join date : 2012-02-06

Location : Suffolk

Page 1 of 3 • 1, 2, 3

Similar topics

Similar topics» Ogier confirms plans for 2018

» Otto's plans

» future plans for wrc?

» Solido future plans Facebook video

» My projects

» Otto's plans

» future plans for wrc?

» Solido future plans Facebook video

» My projects

Page 1 of 3

Permissions in this forum:

You cannot reply to topics in this forum